After I published two sketch videos on IEC 61850 information exchange services and the mapping to MMS, I discuss simple interface options for the last meters between a device that implements the role of IEC 61850 server, GOOSE publisher, and GOOSE subscriber, and the underlying huge world of a myriad of other controllers.

The standard series IEC 61850 and IEC 61400-25 (Wind Power Plants) provide a comprehensive set of standardized information or device models (Logical Nodes, Data Objects, Data Attributes, ...) for a wide range of use cases in the electric power domain (protection, automation, supervision, monitoring, control, ...) and for general applications beyond the electrical world. By the way, tell me where electricity is not a crucial resource in factories, buildings, petrochemical plants, homes, ... it is all over ... required 24/7. These series also comprise information exchange mechanisms like Reporting, Logging, Control, GOOSE, Sampled Values, ... mapped mainly to MMS in IEC 61850-8-1 ... other mappings like mappings to XML and XMPP in IEC 61850-8-2 or MMS, Web Services, IEC 60870-5-104, DNP3, OPC XML DA, ... in IEC 61400-25-4. The most crucial part of IEC 61850 and IEC 61400-25 is the System Configuration Language (SCL, IEC 61850-6).

Many applications use only a very small set of models (a few measurements, control signals, and status signals), a small set of information exchange services, and a simple subset of SCL. Critic comes from experts of various domains: Why do I need to have a complex and comprehensive IEC 61850 stack to implement a simple subset of these standard series? Is there another solution? The wind power plant people developing and maintaining IEC 61400-25 believing that five (5) mappings would help in this regard - really? So, the discussion is still going on.

A very simple solution has been implemented in various projects: Notation of a subset of the information models and the payload of the messages in JSON. The exchange services could be mapped to various transport mechanisms like MQTT or HTTP ...

This approach would KEEP the models as they are - NO mapping required, just another notation (JSON instead of MMS named Variables etc.). Even SCL could be used.

Whenever there is a need to communicate from a device that plays the role of an IEC 61850 server, GOOSE publisher, GOOSE subscriber, to an underlying (likely simple) device (for the last meters) the decision usually is to use some other communication stacks from a set of 100+ solutions like CAN, Modbus, many fieldbusses, EEBUS, Sunspec, ... and private digital solutions, or even wires only ...

Any of these need to MAP from one standard to another standard, e.g., map MyIED/myMMXU1.Hz.mag.f (measurement of frequency) to register 2246 in one application and to 9817 in another ... hm, that is feasible BUT means a lot of configuration and documentation ... outside the definitions and tools provided by IEC 61850.

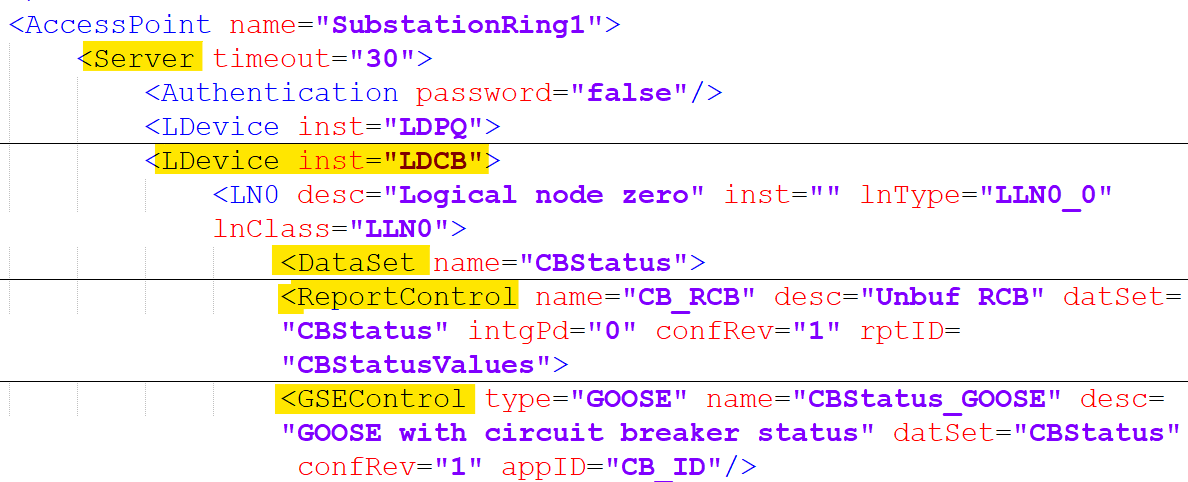

A more reasonable approach would be to use JSON, e.g., to define a DataSet (semantically equivalent to IEC 61850 and MMS) and the report message payload as shown in the figure below:

Please check a couple of blog posts published a few years ago for more details and discussions:

https://blog.nettedautomation.com/2019/07/iec-61850-8-2-versus-iec-61850-8-1.html

https://blog.nettedautomation.com/search?q=mqtt

https://blog.nettedautomation.com/2019/10/iec-61850-for-monitoring-data-private.html

Unfortunately the Beck IPC com.tom Web PLCs with support of IEC 61850, ... disappeared ...

Please let me know your opinion ...

.jpg)